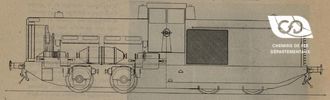

The principle of gear control

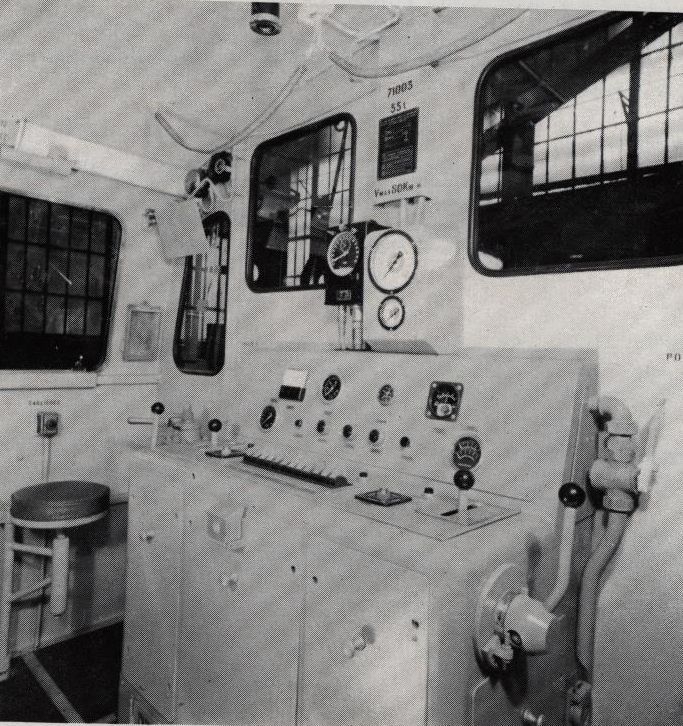

The control lever placed on the console, can occupy 4 positions:

- direct locomotive brake,

- engine idling, transmission disengaged,

- transmission clutch, engine at idle,

- engine acceleration.

A speed manipulator gives the following possibilities :

- work of the locomotive on the hump,

- manual control of the gearbox,

- automatic order,

- engine" overspeed control with 15% load reduction at 8th speed.

The main control available to the locomotive engineer, acts on an air regulator which, via an electro-pneumatic distribution block, controls the engine speed in the "hill-up" position of the speed manipulator, and the engine torque for all other positions of this speed manipulator.

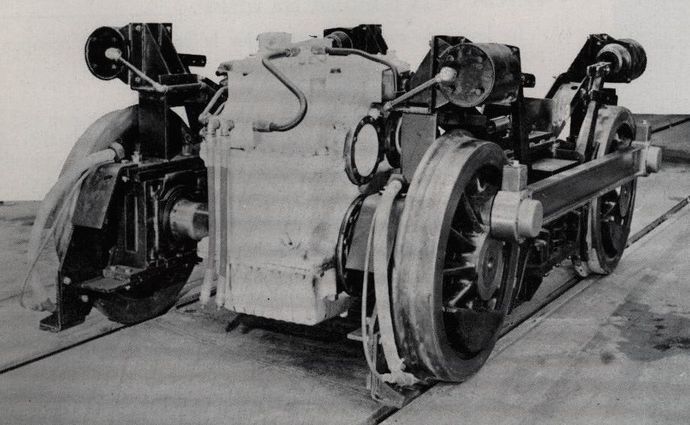

On this machine with automatic or manual gearshift control, the transmission combination shift cycle is fully automatic

In manual control, the judicious choice of the combination to be engaged and the moment when this operation must be carried out is up to the driver, who, by moving the gearshift lever from one stable position to another stable position, will trigger the gearshift in order :

1° an impulse which will start the stage change cycle,

2° a new excitation of the solenoid valves controlling the rods which will correspond to the stage chosen by the mechanic, and will allow the end of the cycle for the passage of the suit.

In automatic control, the gearshift lever must be in the CA2 or CA3 markings. In this case, the choice of the combination to be engaged and the moment when this operation is judicious, is entrusted to an automatic system which prevents the mechanic from having to change the combination.

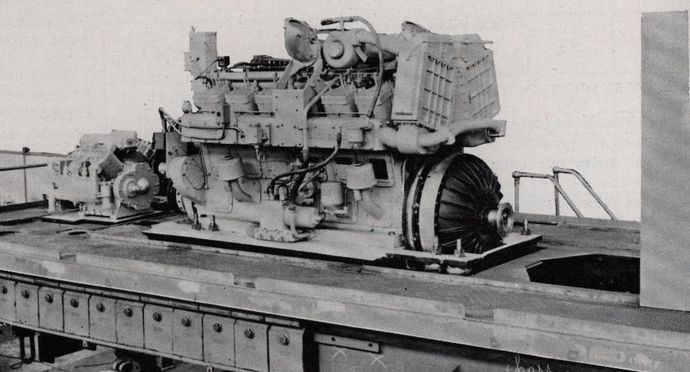

The choice of the "moment" at which the stage change must be triggered when the stages are raised or lowered is given by the engine, taking into account its instantaneous speed and load. The latter is interrogated by two centrifugal contactors, one of which gives a test at rated speed and the other a test at the lower operating speed of the engine. Finally, a microswitch tests the position of the rack and thus the load of the motor.

In conclusion, for an instantaneous engine speed higher than 1,640 rpm and for a load less than or equal to 74%, the engine will command the stage change to the upper stage, and for an instantaneous engine speed lower than 1,180 rpm, it will command the stage change to the lower stage.

These two tests together constitute the "engine test" or the choice of the "moment".

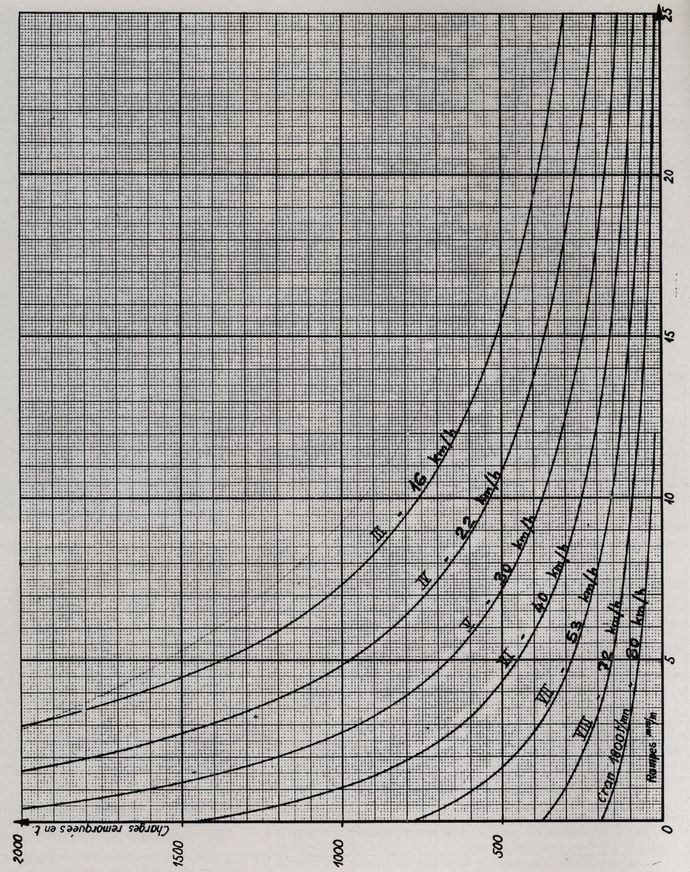

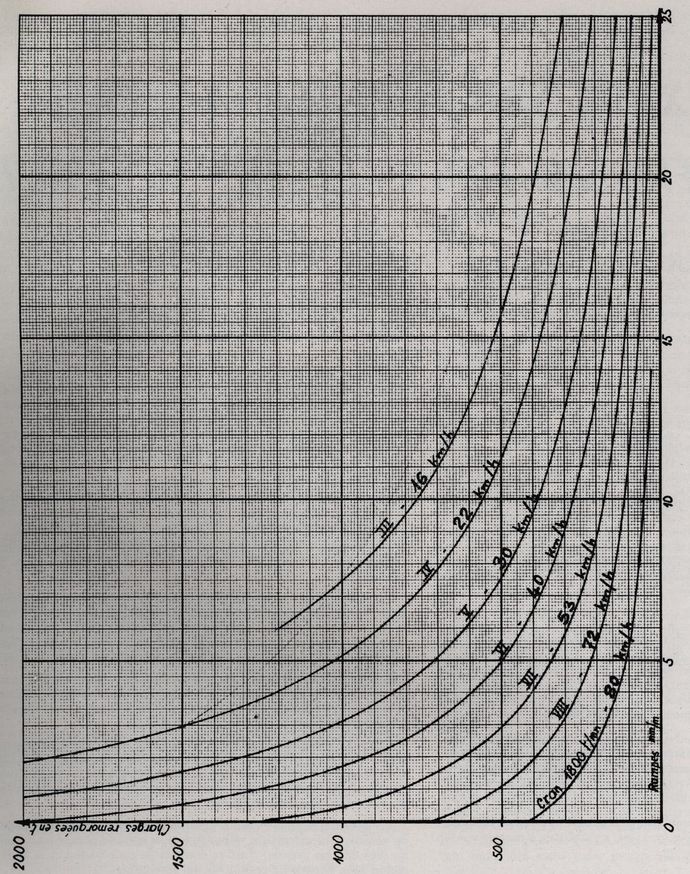

The choice of the combination to be engaged is given by the speed of the machine. This is the "axle test". A tachometric dynamo constantly gives a voltage proportional to the speed of the machine. This voltage is applied to the terminals of a cabinet with three voltage relays connected in parallel and whose adjustment by fixed resistors, according to their excited or non-excited state, makes it possible to carry out the 8 combinations according to the logical diagram below.