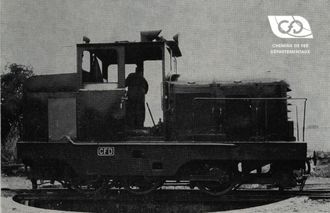

Locomotives with equipment housed in one or two hoods

The first arrangement, with hood and single cab, leads to an economical design, and is generally adopted for all units of moderate power, with which it is possible to give the hoods sufficiently small dimensions to provide good visibility to the driver in both directions of travel. The arrangement with two driver's cabs is necessary for reasons of visibility when power becomes important, or when, as multiple unit operation is frequent, it is advisable to allow personnel to move from one unit to the other.

To better protect the driving crew in the event of a collision, and also for aesthetic reasons, modern two-cab locomotives generally have a small "nose" at each end, topped by the slightly recessed driver's cab.

In the United States, single-cab locomotives are widespread, even for power ratings in excess of 1500 hp. In this case, two-man operation, which is the rule in the United States, is necessary because of the large dimensions of the hoods, which limit visibility.

When, as is frequently the case in the United States, the traction of trains requires significant power, several units operating as a multiple unit are used; most often, only the head unit, or the two extreme units, are equipped with a driver's cab.

In the case of single-cab and hooded locomotives, the chassis alone contributes to the overall strength; it must be particularly robust and, due to its low height, relatively heavy.