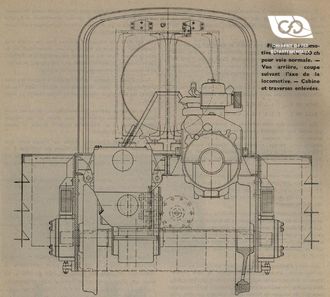

The driver facing the controls

The driver does not have to manoeuvre the throttle control between each gear change, because a very simple mechanical device cuts off the injection of the engine, whose speed will be changed before disengagement, and gradually returns the injection to its original position during re-engagement.

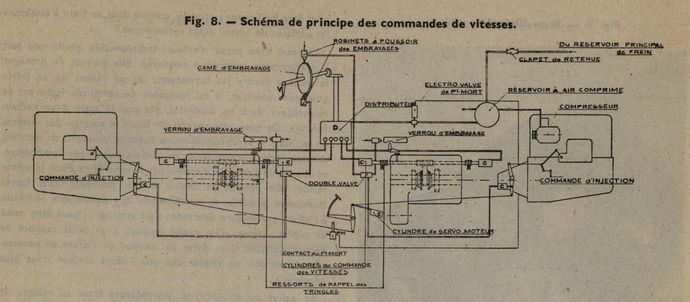

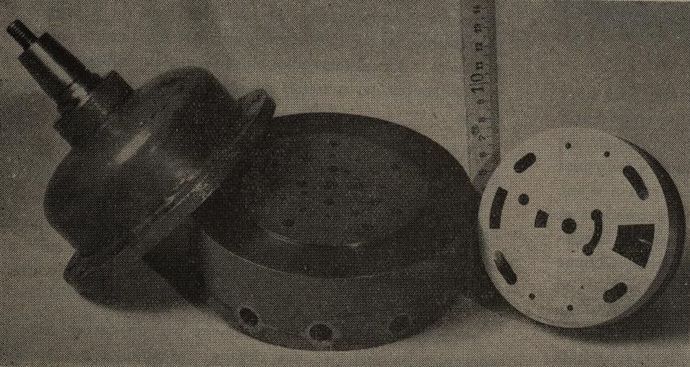

Neutral can be achieved at any time by fully depressing the clutch pedal. An electrical contact (P.M.) is reversed each time the clutch pedal is fully depressed. It turns on or off a solenoid valve (E.V.) in the compressed air supply circuit to the distributor.

For example, when the locomotive is stationary and the driver wants to start, he places the hand wheel in the 1re_1 position, disengages the clutch fully, places the throttle lever in the start position and slowly raises the clutch pedal. He can then adjust the throttle lever, taking into account the train load and the desired starting speed. As soon as he has reached a reasonable speed, he only has to turn the hand wheel half a turn, then another half turn and so on until the locomotive reaches maximum speed.

Thanks to the presence of the freewheel, no wrong operation can be made . Thus, without any inconvenience, and at full speed, it is possible to place the handwheel on all lower gears.

If, by mistake, the mechanic clutches at a speed too high for the speed of the tractor, the only disadvantage is to stall the engine; but this always happens, thanks to the device described above, when the engine is at low revs, so neither the engine nor the clutch has to suffer.

In the event of an emergency stop, the clutch pedal is pressed down fully This will bring the engines to idle, the clutches disengaged and the gearboxes returned to neutral.

It is also possible, without any inconvenience, to change from one gear to another without having to go through the intermediate gears, which simplifies driving when, in the middle of the track, the train has had to slow down.

The shuttle controls on each deck are operated by compressed air using the same compressed air cylinders as those acting on the gear rods, the shuttle lever acts on Westinghouse push taps.

It should be noted that with this device you can, for example, drive in 3rd gear on one motor and in 4th gear on the other for as long as you want. Their speeds will be different, you just have to watch that they stay within the usual limits.

On the other hand, it should be noted that this arrangement gives 11 speeds and that in some ramps a load is towed better in 4/5 than in 4/4 or 5/5.